Latex/ Neoprene/Nitrile/PU/PVC

Nitrile VS Latex Coated Gloves

HPPE,high-performance polyethylene,also known as HMPE,high-modulus polyethylene or UHMWPE, Ultra-high-molecular-weight polyethylene.

It has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very tough material, with the highest impact strength of any thermoplastic presently made.

UHMWPE is odorless, tasteless, and nontoxic. It embodies all the characteristics of high-density polyethylene (HDPE) with the added traits of being resistant to concentrated acids and alkalis, as well as numerous organic solvents.[4] It is highly resistant to corrosive chemicals except oxidizing acids; has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating (see boundary lubrication); and is highly resistant to abrasion, in some forms being 15 times more resistant to abrasion than carbon steel. Its coefficient of friction is significantly lower than that of nylon and acetal and is comparable to that of polytetrafluoroethylene (PTFE, Teflon), but UHMWPE has better abrasion resistance than PTFE.

They are at least 8 times stronger than steel wire ropes on a weight-for-weight basis. Since they are thinner and lighter, they are significantly easier to handle compared to steel and conventional fiber ropes. This means more effective logistics, shorter tie-up times, reduced fuel consumption, increased speed and safety.

HMPE fiber has a melting point between 144ºC and 152ºC. The tenacity and modulus decrease at higher temperatures but increase at sub-zero temperatures. There is no brittle point found as low as -150ºC, so the fiber can be used between this temperature and 70ºC. Brief exposure to higher temperatures will not cause any serious loss of properties.

Aramid fibers are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in bicycle tires, marine cordage, marine hull reinforcement, and as an asbestos substitute.[1] The name is a portmanteau of "aromatic polyamide". The chain molecules in the fibers are highly oriented along the fiber axis. As a result, a higher proportion of the chemical bond contributes more to fiber strength than in many other synthetic fibers. Aramides have a very high melting point (>500 °C)

Aramid fiber characteristics

Aramids share a high degree of orientation with other fibers such as ultra-high-molecular-weight polyethylene, a characteristic that dominates their properties.

* good resistance to abrasion

* good resistance to organic solvents

* nonconductive

* very high melting point (>500 °C)

* low flammability

* good fabric integrity at elevated temperatures

* sensitive to acids and salts

* sensitive to ultraviolet radiation

* prone to electrostatic charge build-up unless finished

Aramid is a class of strong, synthetic fibers. In the family are the trademarked names Kevlar, Nomex, Twaron, and Technora belonging to various companies. Kevlar is a trademarked name owned by DuPont for one of those fiber compositions.

Nylon: Nylon is a durable, abrasion resistant and resilient fiber. Over all it is a well wearing and resistant to insects, fungi and mildew.

Polyester: Polyester is much like nylon; durable, resistant to abrasions, insects, fungi, and mildew, but it’s also resistant to sunlight (UV Rays) where as nylon isn’t. The fiber is slightly stretchy which makes the glove form to your hand.

Latex: Latex palm gloves offer strong grip, dexterity, abrasion and puncture-resistance. The coating makes gloves suitable for use in the automotive industry, construction work and other general purposes. Latex has very high elasticity and exceptional grip capabilities; it can also withstand high temperatures and offers great tear resistance. Although it resists alcohols, latex coated gloves should not be used around most hydrocarbon and organic solvents, such as gasoline and kerosene.Note: Those with Latex allergies may not be able to use gloves with this coating type.

Neoprene: Neoprene is part of the chloroprene family and was the first commercial synthetic rubber created by the DuPont Corporation. It has good abrasion and cut resistance and is resistant to the effects of aging, sunlight, ozone, oxidation and weather.

Nitrile: Nitrile is a co-polymer of acrylonitrile and butadiene. It is a synthetic version of latex (but does not contains the latex proteins) that is strong, does not cause allergic reaction and therefore has a wider range of applications. It offers excellent resistance to punctures and tears and stands up well to oil, making it a good choice for handling small oily parts.

Polyurethane(PU): A versatile polymer that can be used to coat a range of glove materials for added protection. It has the quality of grip-ability without being sticky. Polyurethane’ssoftness, combined with great puncture and abrasion resistance, make it the perfect coating for several of Kinco’s garden glove styles. It provides grip and is puncture resistant, without reducing touch sensitivity.

Polyvinyl Chloride(PVC): Polyvinyl chloride is a thermoplastic polymer that is used to coat the outside of gloves in order to provide protection from chemicals, punctures, cuts and abrasion. It is primarily designed to keep hands protected from oil and other slippery substances while providing a superior grip. Kinco offers a selection of fully coated PVC gloves, including oil resistant, textured finish, knit wrist or gauntlet, and insulated styles. PVC gloves are frequently worn by warehouse workers, farmers, agriculturists, construction workers and commercial fishermen.

Cut-resistant gloves are those designed to protect the wearer's hands from cuts while working with sharp tools. They can be divided into metal mesh gloves, cut-and-sewn, and seamless knitted gloves.

Metal mesh gloves are a form of chainmail, and are made of rings of stainless steel. They are typically used in food applications.

Cut-and-sewn gloves can be made using a cut-resistant material or by using conventional materials with full or palm lining of cut-resistant materials. The materials are cut to shape and sewn into a glove.

Seamless knitted gloves are knitted in one piece by a flat knitting machine. The cut protection is provided by high performance materials such as Para aramid (Twaron, Kevlar), HPPE (High Performance Poly Ethylene, Dyneema, Spectra), special PVA yarns (SupraBlock) or steel wire and fiberglass yarns. Knitting machines are commonly classified using gauge, and can range from 7 gauge all the way through 18 and 21 gauge. The gloves are often coated with solid or foamed latex, nitrile or polyurethane.

Cut resistance has many dimensions such as force, direction, sharpness of the blade, length of the cut and flexibility of object. Different products should be evaluated in relation to the expected type of cut risk and environment that they are expected to face.

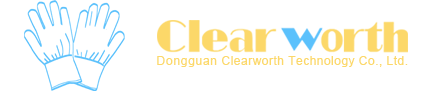

One method of evaluating cut resistance is the EN 388:2016 standard, or "coup" test. EN388 uses a circular rotating blade of 40mm diameter that rotates against the direction of movement. The blade is moving back and forth over a small distance of about 50mm with a load of 5N. The numbers of cut cycles are recorded and compared to a cotton control fabric. A cut resistance index is calculated between "0" and "5" depending on the average number of cycles prior to break-through failure: "0" means 0 to 1.2 cycles; "1" means >1.2 to 2.5 cycles; "2" means >2.5 to 5.0 cycles; "3" means >5.0 to 10.0 cycles; "4" means >10.0 to 20.0 cycles; and "5" means >20.0 cycles.

EN 388 was updated in 2016, and one significant change is the introduction of ISO 13997:1999. EN 388:2016 incorporates a letter A-F to indicate the cut resistance of A<2N, B<5N, C<10N, D<15N, E<22N and F<30N. This is more in line with the new North American standard of ANSI/ISEA 105-2016 that is using a system of A1-A9 cut levels.

ASTM F2992-15 is similar to ISO 13997:1999 in that the test is carried out on a tomodynamometer (or TDM). A cutting edge (usually a razor blade) under a specified load is moved across a sample material. When the blade cuts through the material, the cut-through distance is calculated. This test is repeated with different loads to determine the calculated cutting load for the sample material. The result is compared to the levels outlined in ANSI/ISEA 105-2016, and the ANSI Cut Level is determined.

ANSI A1 Cut - 200-499 GRAMS TO CUT

Assembly, Maintenance, Material Handling, and Shipping and Receiving

ANSI A2 - 500-999 GRAMS TO CUT

Assembly, Appliance Manufacturing, Automotive, Construction, Maintenance, Material Handling, and Cut Metal Handling

ANSI A3 - 1,000-1,499 GRAMS TO CUT

Assembly, Appliance Manufacturing, Automotive, Construction, Maintenance, Material Handling, and Cut Metal Handling

ANSI A4 - 1,500-2,199 GRAMS TO CUT

Appliance Manufacturing, Automotive, Construction, Glass Handling, Machining, Metal Handling, Metal Cut Stamping and Paper Production

ANSI A5 - 2,200-2,999 GRAMS TO CUT

Appliance Manufacturing, Automotive, Construction,Glass Handling, Machining, Metal Handling, Metal Cut Stamping and Paper Production

ANSI A6 - 3,000-3,999 GRAMS TO CUT

Appliance Manufacturing, Automotive, Construction, Glass Handling, Machining, Metal Handling, Metal Cut Stamping and Paper Production

ANSI A7 - 4,000-4,999 GRAMS TO CUT

Assembly or movement of large, bulky or heavy objects with sharp edges. Also recommended for Assembly or

Cut movement of items that are difficult to grip

ANSI A8 - 5,000-5,999 GRAMS TO CUT

Assembly or movement of large, bulky or heavy objects with sharp edges. Also recommended for Assembly or

Cut movement of items that are difficult to grip

ANSI A9 - 6,000+GRAMS TO CUT

Assembly or movement of large, bulky or heavy objects with sharp edges. Also recommended for Assembly or

Cut movement of items that are difficult to grip

Different kind coated gloves:

1) According to surface treatment, including smooth finish, sandy finish coated glove, foam finish work glove, double layer finish and so on. Smooth nitrile provides more dexterity, sandy nitrile provide better grip, foam nitile is more effective in water and oils resistant and protects hands from puncture and cold.

2) According to the liner material, nitrile coated glove including polyester liner, nylon liner, nylon with spandex liner, cotton jersey liner, cotton interlock liner, HPPE liner and so on. Nylon liner is a durable, abrasion resistant and resilient fiber. Over all it is a well wearing and resistant to insects, fungi and mildew. Polyester liner is much like nylon; durable, resistant to abrasions, insects, fungi, and mildew, but it’s also resistant to sunlight (UV Rays) where as nylon isn’t. Nylon with spandex liner has more dexterity. Cotton jersey liner, cotton interlock liner, sweat absorbing. HPPE liner is cut resistant.

3) According to the coated position, including palm coated nitrile work glove, half coated nitrile coated work glove, full coated nitrile work glove, double layer nitrile coated gloves. Palm coated provides good grip save coating material, less cost and breathability at back, more comfortable. Half coated provides good grip and water resistant from palm to finger and not compromised to breathability and comfort. Fully coated get full protection against water, abrasions and puncture and protectd hands from the cold.

Latex is a material that is taken from rubber trees. These are the materials commonly found in commercial gloves that you can buy in the market. In the past, they are the preferred choice for medical purposes and for cleaning.

These days though, more and more industries are turning to Nitrile Coated Gloves for the same reasons pointed above. Nitrile Coated Gloves offer better quality and resistance to damage than regular latex gloves, which makes them a better choice for a variety of applications.

On a scale of 1-10, the chemical resistance of nitrile coated gloves is at 10 while latex is only at 5. The puncture résistance of nitrile coated gloves is also at 10 while the puncture resistance of latex gloves is only at 4.

Nitrile coated gloves are also better for allergy sufferers with its minimal allergy rate of 1% compared to the 3% allergy rating of latex.

On the other hand, latex wins when it comes to dexterity, offering better sensitivity to users. It is also more biodegradable compared to nitrile coated gloves.

Dongguan Clearworth Technology Co., Ltd.